Application of intermediate frequency furnace in industry

The intermediate frequency furnace is a non-electromagnetic induction heating equipment and is widely used in the thermal processing industry. In the industry, it has different applications according to different heating purposes. For example, casting smelting, pre-forging heating, round steel heat treatment, etc. all require intermediate frequency furnace heating, so it is called intermediate frequency. Furnace applications in industry.

Application of intermediate frequency furnace in foundry industry

Medium frequency furnaces are widely used in the foundry industry and have become standard equipment for casting and melting scrap metal equipment. By using intermediate frequency furnaces, foundries can quickly and evenly melt scrap metal materials for the casting process. This efficient heating method can improve production efficiency, reduce production time, and result in better product quality.

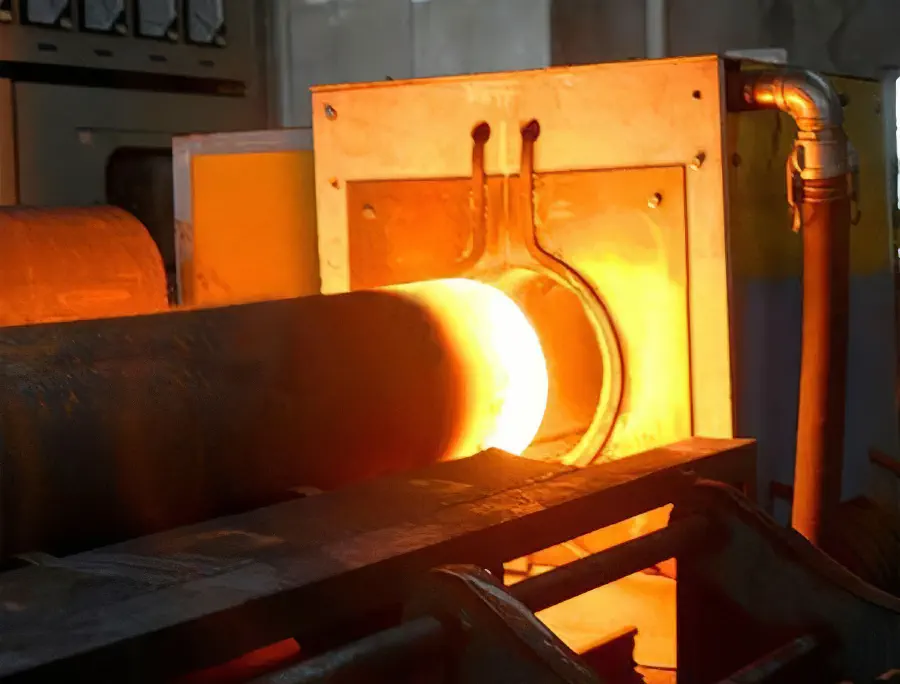

Application of intermediate frequency furnace in round steel heating and heat treatment industry

The application of intermediate frequency furnace in the heat treatment of round steel is often used for quenching, tempering, annealing, and normalizing of metals. According to different heat treatment process requirements, the round steel is heated to different temperatures, and spraying is used to achieve the quenching and tempering process. Requirements, the heating temperature ranges from 100 degrees to 1200 degrees, and the quenched and tempered metal material is generally alloy steel such as round steel; these processes are crucial to improving the mechanical properties, wear resistance and corrosion resistance of the metal. The intermediate frequency furnace can precisely heat specific workpieces and parts to ensure consistency and repeatability of heat treatment results.

Application of intermediate frequency furnace in the forging industry

Its application in the forging industry is mainly used in the pre-forging heating process. For different materials of alloy steel, alloy copper, aluminum and other metals, it is heated to different required forging temperatures. Qualified forging blanks are provided to pressure for forging. Intermediate frequency furnaces mainly exist in the form of forging heating production lines in the forging industry, which can reduce forging costs and improve forging quality.

Application of intermediate frequency furnace in billet heating industry

In production processes such as continuous casting and rolling, the steel billet needs to be heated to an appropriate temperature to ensure the smooth progress of the rolling process. The intermediate frequency furnace is used to supplement the temperature online during this process to ensure that the temperature of the steel billet is uniform, thereby improving the quality of the final product.

Application of intermediate frequency furnace in rolling heating industry

In processes such as steel ball rolling, special-shaped steel rolling, and rebar rolling, the material needs to be preheated to a suitable temperature to facilitate processing. The intermediate frequency furnace ensures high efficiency of the heating process and optimization of energy utilization with its rapid heating capability.

Application of intermediate frequency furnace in metal forming and heating industry

During metal forming processes such as forging and extrusion, the material must be heated to a sufficient plasticity temperature. The intermediate frequency furnace provides a fast and precise method to heat materials to the required plastic state, thereby improving the efficiency of the molding process and product quality.